(The picture is for reference only,the appearance and size are subject to the actual factory equipment.)

BED FRAME

High-Grade Cast Iron

The frame has undergone precise finite element force analysis. The core frame of the equipment adoptshigh-gradeQT500-7 andgray iron250 castings, and the triangular interconnection design ensures the stability under high tonnage impactforce.

High Standard Welding

The welding process adopts CO2 protection welding, and the welding place adopts the full welding process to ensure that the welded work piece is firm and beautiful.

Stress Relief Treatment

Castings and welded support tables are subjected to multiple tempering, annealing and other heat treatment processes to ensure long-term use without deformation.

Precision Machining

Different fixtures are designed for different work pieces, and high-precision multi-axis machining centers are used to finish the work pieces, ensuring the consistency of precision before and after clamping.

Strict Testing

Using a high-precision micrometer U meter, in conjunction with a high-stability marble platform and a marblesquare, the work piece is accurately measured, the processing quality of each work piece is strictly controlled, and the level of control is ensured to ensure that the assembly accuracy of the wholemachine meets the

standards of high-precision machine tools.

Standard 13-axis

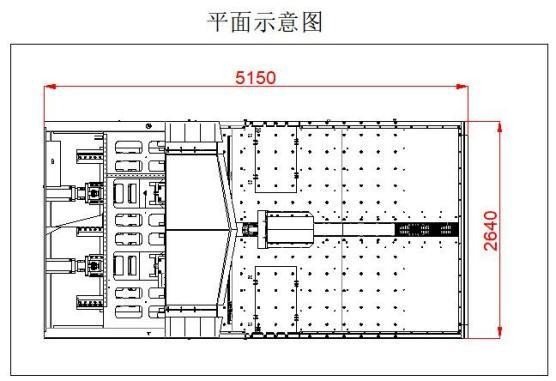

Technical Parameters and Specification Description

Project | Unit | 2000p |

Fastest bending speed | sec/time | 0.2 |

longest bend length | mm | 2000 |

Bendheight | mm | 170 |

Rated voltage | v | 380 |

Peak power | KW | 25 |

Average power | KW | 2.5 |

Noise | 分贝 | 50 |

Overall dimension | mm | 5100*2625*3300 |

Total mass | kg | 16000 |

Maximum bending plate thickness | mm | 201Stainlesssteel 0.8 304Stainlesssteel1.0 Coldrolledsheet 1.2 Aluminumplate 1.6 |

Minimum material thickness | mm | 0.35 |

Minimum innersize offour-sidedforming | mm | 140x190 |

Minimum inner dimension of bilateral forming | mm | 140 |

Maximum bending size | mm | 2000x1250 |

Numberofcontrol axes | Piece | 13 |

Operation Requirement

Electricity: ( Industrial stabilizer is suggested)

(1) Voltage: 380V

(2) Frequency: 50Hz

(3) Voltage stability + 5%

(4) Voltage regulation: <2%

Sheet metal:

Homogeneous, smooth and clean.

Assist gas:

Purified dry compressed air and high purity

oxygen (O2) and nitrogen (N2) purity not

less than 99.9%

Compressed air supply device

(1) Pressure: 14 bar (2) Volume: 1 m

The warranty period of the whole equipment (except for the vulnerable parts and consumables such as mould, hydraulic oil, natural disasters, war, illegal operation and human damage) is one year, and the warranty period shall be calculated from the date of signature by the demander. The supplier shall be responsible for free repair and replacement of parts (except for vulnerable parts and consumables such as mould, hydraulic oil, etc.) which are within the scope of quality assurance during the warranty period. If the equipment failure or equipment damage caused by abnormal power supply of the demander, deterioration of equipment working environment,improper operation and force majeure factors outside, it is not a free warranty item. The supplier shall provide life long maintenance and long-term free consulting services, except for the buyer’s breach of contract.

After receiving the maintenance notice from the demander, the supplier shall assign a special person to follow up and reply within 2 hours. If the problem cannot be solved under the guidance of telephone, fax, network and other communication channels, the supplier can send maintenance personnel to the buyer’s site within 24 hours(excluding the roadtime).